Tutorial: How to Connect to PLC from Remote Location

This guide explores how to connect to a PLC from a remote location, covering the different technologies, steps, and security concerns involved in remote PLC access. It highlights the benefits of remote access, including reduced downtime and cost savings.

Introduction

Imagine you're overseeing an industrial process, and suddenly, there's a glitch. Instead of rushing to the plant, wouldn’t it be better to resolve it from the comfort of your home? Well, that’s where remote access to PLCs (Programmable Logic Controllers) comes in handy! Being able to connect to PLC from remote locations isn’t just about convenience—it’s about ensuring continuous operations and reducing downtime.

In this article, we'll dive deep into how to connect to PLC from remote locations and why it's crucial for modern industries.

What is a PLC?

Before we dive into the technical details, let’s break down what a PLC is. A Programmable Logic Controller (PLC) is an industrial computer used to control various types of machinery and processes. It takes inputs, processes them according to a programmed set of instructions, and then generates outputs to control devices like motors, valves, or lights.

These devices are crucial in automation and are commonly found in industries like manufacturing, energy, and logistics. Now that we know what a PLC is, let’s explore why connecting to it remotely is essential.

Why Remote Connectivity for PLCs Matters

Imagine being able to control or monitor your entire factory's operation from the comfort of your home. That's the power of remote PLC connectivity. Remote access allows engineers and technicians to monitor, troubleshoot, and even reprogram PLCs without being physically present.

In scenarios where the PLC is in a hard-to-reach or hazardous location, remote access ensures that you can still maintain control over the operations without risking personal safety or wasting time traveling to the site. This level of connectivity leads to improved uptime, faster response times, and reduced operational costs.

Requirements for Remote PLC Access

If you want to connect to PLC from remote location, you need both hardware and software components working in harmony:

- Hardware: Typically, you’ll need routers, modems, and industrial gateways to bridge your PLC to a network.

- Software: Remote access tools like SCADA systems, programming environments (like TIA Portal or RSLogix), or cloud-based platforms are essential.

- Network Configuration: The setup usually involves a static IP address, VPN, or port forwarding, allowing secure communication between the PLC and the remote system.

Types of PLC Remote Access

There are several ways to connect to PLC from remote location, each with its pros and cons:

- Direct Access via Static IP: A simple solution that involves configuring the PLC to have a static IP. However, this method can be risky if proper security measures aren’t implemented.

- VPN (Virtual Private Network): One of the safest methods. It creates an encrypted tunnel between your device and the PLC network, keeping sensitive data protected.

- Remote Desktop: Accessing a PLC through a remote desktop tool can be convenient, especially if the programming software is installed on a PC at the site.

- Cloud-Based Solutions: Cloud platforms offer more flexible, scalable, and secure remote access options. These solutions are gaining popularity with the rise of Industry 4.0.

Benefits of Remote PLC Connections

Connecting to a PLC from a remote location offers several benefits:

- Increased Efficiency: Remote access allows for immediate troubleshooting and adjustments without the need for on-site presence.

- Cost Savings: Reduces travel expenses and downtime associated with physical visits.

- Enhanced Monitoring: Provides real-time data and control over PLC operations, improving response times and operational management.

- Safety: Minimizes the need for personnel to enter hazardous or difficult-to-reach areas.

- Enhanced Flexibility: Allows access from anywhere, providing greater control over industrial operations.

Challenges and Solutions in Remote PLC Access

While remote PLC access offers many benefits, it also presents challenges:

- Security Risks: Ensure strong encryption and authentication to protect against unauthorized access.

- Network Latency: Slow internet connections can affect performance; consider upgrading your network if issues arise.

- Configuration Complexity: Proper setup is crucial for reliable remote access; consult with IT professionals if needed.

How to connect to PLC from remote location [2 ways]

Remote control of a PLC is essential for monitoring and maintaining automation systems without being physically on-site. There are two primary methods to achieve this: using a Public IP address or using a VPN (Virtual Private Network).

Method 1. Using a public IP

This method involves exposing your PLC to the internet via the public IP address assigned to your router. By forwarding the necessary ports, you can access the PLC from anywhere remotely.

Steps to connect to the PLC from a remote location using a public IP:

Step 1. Connect PLC to Router: Connect your PLC to the Ethernet port of the router.

Step 2. Obtain Public IP: Check your router’s public IP address. This is the IP address assigned by your Internet Service Provider (ISP) and allows external access.

Step 3. Configure Port Forwarding: In the router’s web interface, set up port forwarding for the PLC communication port (usually port 102 for S7 communication or the specific port your PLC uses). Forward this port from the router's public IP to the PLC’s local IP address.

Step 4. Access PLC Remotely: Using your PLC programming software (e.g., TIA Portal), enter the public IP address and port to connect remotely.

Considerations:

- Ensure your ISP provides a static public IP or use a dynamic DNS service if the IP changes.

- Be cautious about security risks since your PLC will be exposed to the internet; consider adding firewall rules or other protections.

Method 2. Using VPN (Virtual Private Network)

VPN creates a secure, encrypted tunnel between your remote device and the local network where the PLC resides. This is safer than exposing ports publicly.

Steps to connect to the PLC from a remote location using a VPN:

Step 1. Connect PLC to Router: Connect the PLC via Ethernet to the router on-site.

Step 2. Set Up VPN Server on Router: Enable and configure the VPN server (usually OpenVPN or IPsec) on the router.

Step 3. Configure VPN Client on Remote Device: Install and configure a compatible VPN client on your remote PC or device. Use the VPN credentials/configuration provided by the router.

Step 4. Establish VPN Connection: Connect your remote device to the VPN, which will place it virtually on the same network as the PLC.

Step 5. Access PLC Remotely: Using the PLC software, connect to the PLC’s local IP address as if you were on-site.

Benefits:

- Secure and encrypted connection.

- No need to expose PLC ports to the internet.

- Works reliably even if your ISP changes your public IP address.

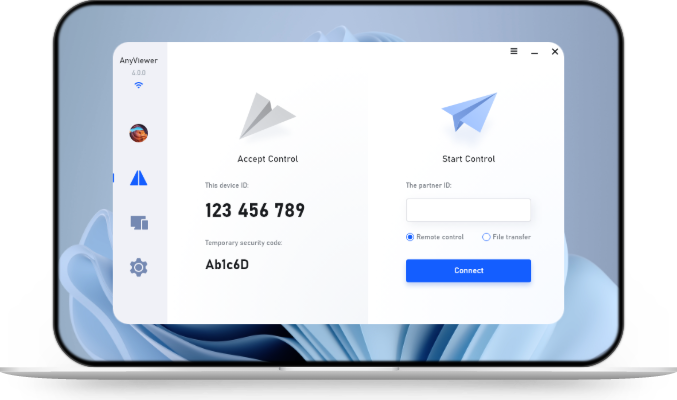

Bonus tip: Using AnyViewer for remote access to PLC engineering workstations

While direct control of PLCs isn't supported by AnyViewer, this powerful remote desktop software can still play a valuable role in your automation setup. You can use AnyViewer to remotely access the PC or engineering workstation that is connected to your PLC locally.

For example, if your PLC is programmed and monitored through a specific software installed on a Windows PC, you can:

- Install AnyViewer on that PC.

- Connect to it remotely from anywhere using AnyViewer.

- Launch the PLC programming or monitoring tool on the remote desktop.

This way, you maintain full control of your automation environment indirectly, without needing to expose the PLC itself over the internet or VPN.

Key Benefits of Using AnyViewer

- Secure Remote Access: Data transmission is encrypted, keeping your automation environment safe.

- High Performance: Smooth control with minimal latency, even for graphically intensive software.

- Cross-Platform Access: Connect from PCs, laptops, or mobile devices—perfect for engineers on the move.

- No Port Forwarding Required: Unlike public IP methods, AnyViewer avoids exposing your network to risks.

- Ideal for Multi-Site Operations: Centralize access to multiple PLC-connected workstations across different facilities.

Step 1. Start by downloading and installing AnyViewer on both your local (control) computer and the remote (target) workstation that is connected to the PLC.

Step 2. Create a free AnyViewer account and log in on both devices to sync them under the same account.

Step 3. On your local computer, go to the device list and find the registered remote workstation. Select the "One-click control" option to initiate unattended access without requiring manual confirmation.

Step 4. Once connected, you will have full control over the remote desktop, including mouse, keyboard, and display. From here, you can open your PLC programming software, HMI interface, or SCADA system—just as if you were sitting in front of the workstation.

- ★Tips: Upgrading to a Professional or Enterprise plan brings several notable benefits, such as:

- Expanding unattended remote access with support for more device assignments and a comprehensive list of connected devices to track connection history.

- Strengthening privacy through Privacy Mode, which hides the screen and blocks remote input on the target computer.

- Streamlining large-scale device management by grouping devices for easier organization and control.

- Allowing you to monitor multiple devices simultaneously with screen walls, offering a multi-view display for better oversight.

- Boosting efficiency with mass deployment features, enabling quick setup across numerous devices at once.

- ...

Conclusion

Connecting to a PLC from a remote location has become a game-changer in industrial automation, offering unmatched flexibility, efficiency, and responsiveness. Whether through VPNs, public IP configurations, or remote desktop tools like AnyViewer, the ability to monitor and control PLC systems off-site minimizes downtime, cuts travel costs, and ensures faster issue resolution. While security and setup are key considerations, the benefits far outweigh the challenges. Especially with tools like AnyViewer, engineers can securely access PLC-connected workstations anytime, anywhere, without exposing sensitive infrastructure. Embracing remote access isn’t just a smart upgrade—it’s becoming a necessity for modern, connected industrial operations.